Corrosion resistance

What do you do when regulatory requirements exceed reasonable engineering controls? – Part 4

In part three of this series, we talked about why regulatory requirements for medical device testing might exceed reasonable engineering controls. In this part, we’ll share the third of five real-life case studies in which we at MED Institute faced these kinds of discrepancies.

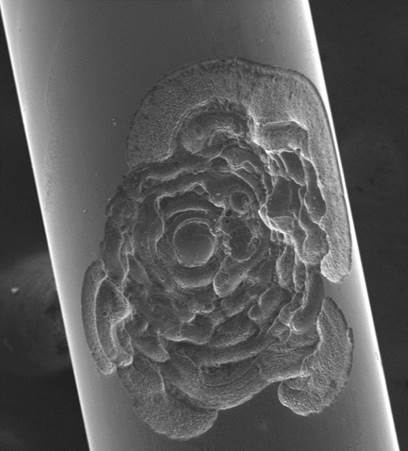

This case study involves a test of the corrosion resistance of implantable metals. All metal implants are potentially susceptible to corrosion, so corrosion resistance is a desirable quality in implantable metals. To test for corrosion resistance, the metal is subjected to an electrical potential in a physiologically relevant environment simulating in vivo conditions.

The company’s requirement as recommended in the ASTM standard, for the test was that the new implant had to have a higher breakdown potential than that of a device that had been successfully used clinically. The regulatory requirement was that the potential required to induce corrosion had to be greater than 600 mV. This case is an example of regulatory bodies and companies reaching for relevant acceptance criteria without sufficient scientific backing. The 600 mV requirement came out of the scientific community to fill a void in the medical device industry for a clinically relevant acceptance criterion.

We had three options for reconciling the discrepancy in the criteria. The first option was to agree with the regulatory body and set 600 mV as the breakdown potential. The second option was to justify to the regulatory body why the company’s requirements were adequate. Justifying the company’s criterion would require educating the regulatory body on the alternative criterion and clarifying the language in the standard. The third option was to work with regulators and come to an agreement on a new solution.

In this case, we preferred the second option because we were confident from experience with clinically used devices that the regulatory body’s requirement had no scientific basis We also felt that it would be a straightforward proposition to clarify the ASTM recommendation with the regulatory body. Furthermore, agreeing to the regulatory body’s requirements would set a precedent that would potentially adversely affect getting other products approved.

For more information about our services and how we can accelerate your product development, please contact us today 855.463.1633| medinstitute.com.

Get email about news, services, and events from MED Institute.

OUR COMMITMENT

We are committed to consistently performing services with high quality, that deliver exceptional results, and add value to the client’s business.

For client surveys sent in 2024, we received ratings of 4.98/5 points (13).