What do you do when regulatory requirements exceed reasonable engineering controls?

Part 5

In part four of this series, we talked about why regulatory requirements for medical device testing might exceed reasonable engineering controls. In this part, we’ll share the fourth of five real-life case studies in which we at MED Institute faced this kind of discrepancy.

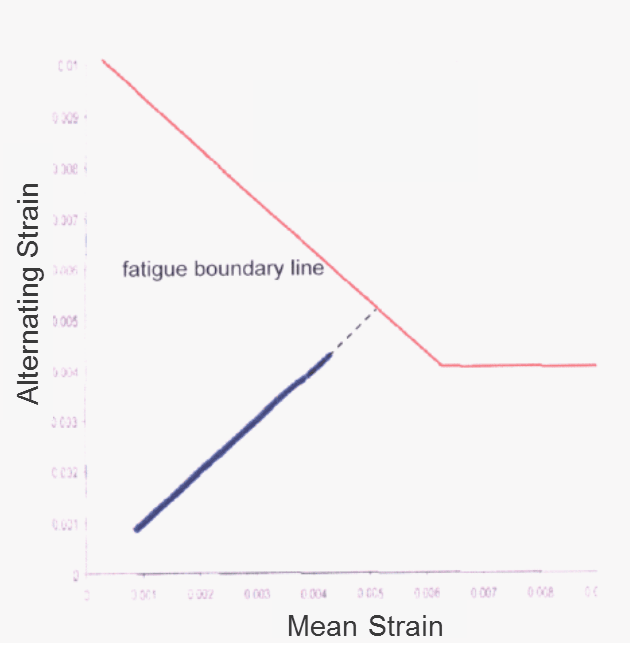

Our fourth case study involves a test of stent durability: the ability of the stent to maintain its structural function in vivo.

The engineering requirement was defined such that the stent must maintain its structural function for 10 years of applied clinically relevant loads.

The regulatory requirement was that testing had to establish that the stent exhibits no fractures under 10 years of clinically relevant loads. There are no standardized clinically relevant loads for most devices. Therefore regulatory bodies and companies often have different clinically relevant loads for a particular device; this mismatch alone can lead to confusion between the regulatory body and the company. For example, one company could set a very severe clinical load and have a test result with fractured samples while another company could set a non-conservative clinical load and have no fractures.

Having seen at least one fracture in this case study, the same three choices existed: Agree with the regulatory body, try to convince it that the company’s criterion is sufficient, or work toward a compromise solution.

Since a fracture was observed, agreeing with the regulatory body would have required making the loading conditions less severe or redesigning the device.

Convincing the regulatory body that the company’s criterion (no loss of structural function) was sufficient would require physician feedback and supporting publications.

Reaching a compromise would be helping the regulatory agency understand clinical loading conditions relative to the loading conditions of the test and the clinical relevance of fractures.

Bridging the gap between differing clinically relevant loading conditions and the clinical relevance of fractures is difficult in a global regulatory environment. Some regulatory bodies expect zero fractures in testing, but clinically, some fractures occur without compromising durability. An uncompromising position on the allowance of fracture during testing isn’t consistent with clinical experience which is more driven by structural function. Our preference in this case was the second choice.

For more information, please visit our website www.medinstitute.com.

Get email about news, services, and events from MED Institute.

OUR COMMITMENT

We are committed to consistently performing services with high quality, that deliver exceptional results, and add value to the client’s business.

For client surveys sent in 2024, we received ratings of 4.98/5 points (13).